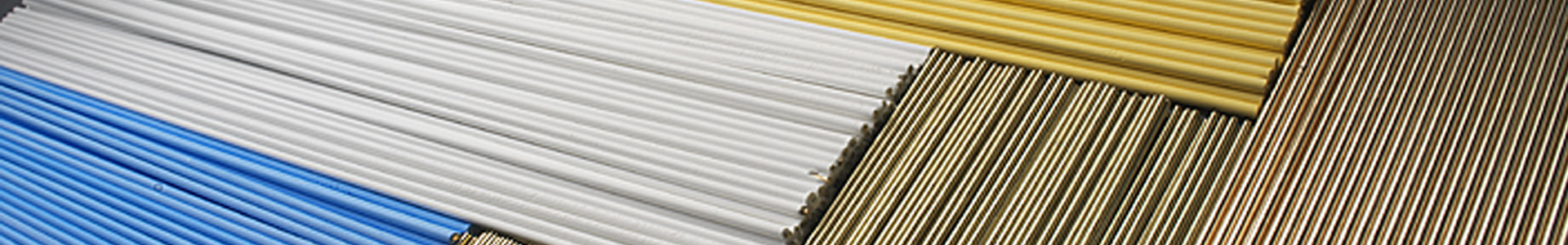

ENVIRONMENTALLY FRIENDLY CADMIUM-FREE BRAZING ALLOYS

Cadmium-free brazing alloys find wide application in the Automotive industry for brazing fittings,

bodywork and assorted construction parts.

The electronics industry is another market for our alloys.

In the refrigeration and HVAC industry, Italbras alloys make flux-free brazing possible in various

manufacturing categories associated with the production and distribution of heat energy.

In the plant construction sector, our whole range of silver-based alloys is used for the production

of components, including the construction of pressure vessels, along with our furnace brazing materials.

APPLICATIONS

We produce specific brazing alloys for the following markets:

Automotive, Electronics, Plumbing, Air conditioning, Heating,

Motor vehicles, Fashion accessories, Costume jewellery,

Eyewear, Measuring and control technology

REACH-494-COMPLIANT CADMIUM-FREE BRAZING ALLOYS

Our silver-based brazing alloys qualify as environmentally friendly as they do not contain metals deemed hazardous for the workplace, according to the RoHS directive and REACH regulation 494.

The alloys can generally be used for service temperatures ranging from -200°C up to +200°C. They can be used for brazing any type of steel, copper and its alloys, or nickel and its alloys. When brazing stainless steel, the zinc in the alloy can result in corrosion issues and so, in specific cases, we recommend using the zinc-free alloy.

Alloys that do not contain tin are particularly good for withstanding dynamic loads.

TABLE OF ALLOYS AND THEIR MAIN PROPERTIES

ROHS-COMPLIANT ENVIRONMENTALLY FRIENDLY COATED BRAZING ALLOYS

Flux-coated brazing alloys, environmentally friendly according to the RoHS directive and REACH regulation 494.

The flux used is type FH 10 in compliance with standard DIN EN 1045.

The directions provided for the use of flux-free brazing alloys also apply to the use of their flux-coated counterparts.

We can produce alloys coated with different percentages of flux to meet your individual requirements.